💙Performance

UHMWPE fibers stand out with their outstanding specific strength, reaching 15 times that of high-quality steel. Its specific modulus is also no less impressive, following closely behind top-grade carbon fibers and becoming one of the world’s leading fibers in terms of specific strength and specific modulus. These characteristics endow UHMWPE fibers with a core position in fields such as aerospace and military protection that pursue light weight and high strength.

2. Lightweight advantage

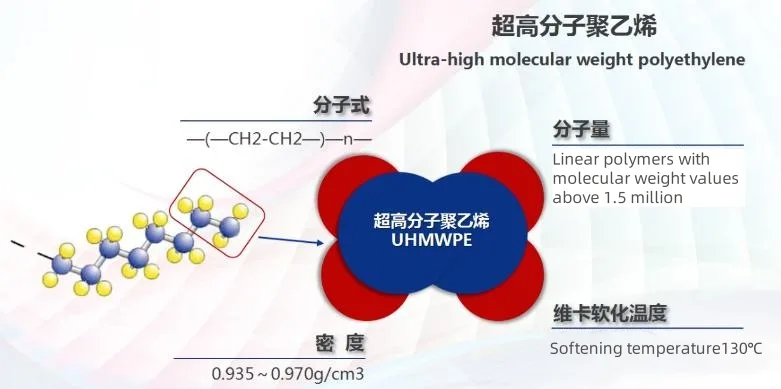

The density of UHMWPE fibers is controlled within the range of 0.97-0.98g/cm³, enabling them to float easily on water and making them one of the engineering plastics with the lowest density. This feature enables UHMWPE fibers to shine brightly in applications such as aerospace and automotive manufacturing where weight reduction is required.

💙Application Field

1. Military protection

UHMWPE fibers play a crucial role in the military field and are widely used in the manufacture of key equipment such as bulletproof vests, bulletproof helmets and protective armor. Its outstanding impact resistance and penetration resistance have significantly enhanced the efficiency and safety of these protective equipment.

2. Aerospace applications

UHMWPE fibers also demonstrate their outstanding performance in the aerospace field. It is widely used in the manufacture of key components such as turbine blades, wing structures and thruster assemblies of aircraft. The lightweight and high-strength properties of this fiber, combined with its excellent impact resistance, enable aerospace vehicles to fly more lightly, efficiently and safely.

3. Applications in the field of safety protection

UHMWPE fibers have also demonstrated their outstanding performance in safety protection. It is made into cut-resistant gloves and puncture-resistant clothing, effectively enhancing the safety of the staff by taking advantage of its excellent cut-resistant and wear-resistant properties.

4. Strengthening of sports equipment

In addition, UHMWPE fibers are also widely used in the manufacturing of sports equipment, such as snowboards, surfboards, bicycle frames and safety helmets, etc. Its high strength and high wear resistance have significantly enhanced the performance and durability of sports equipment.

5. Applications in the medical and health field

UHMWPE fibers also play a significant role in the medical and health field and are often used as dental tray materials, medical implants, and plastic sutures, etc. Its biocompatibility and durability make medical devices safer and more effective.

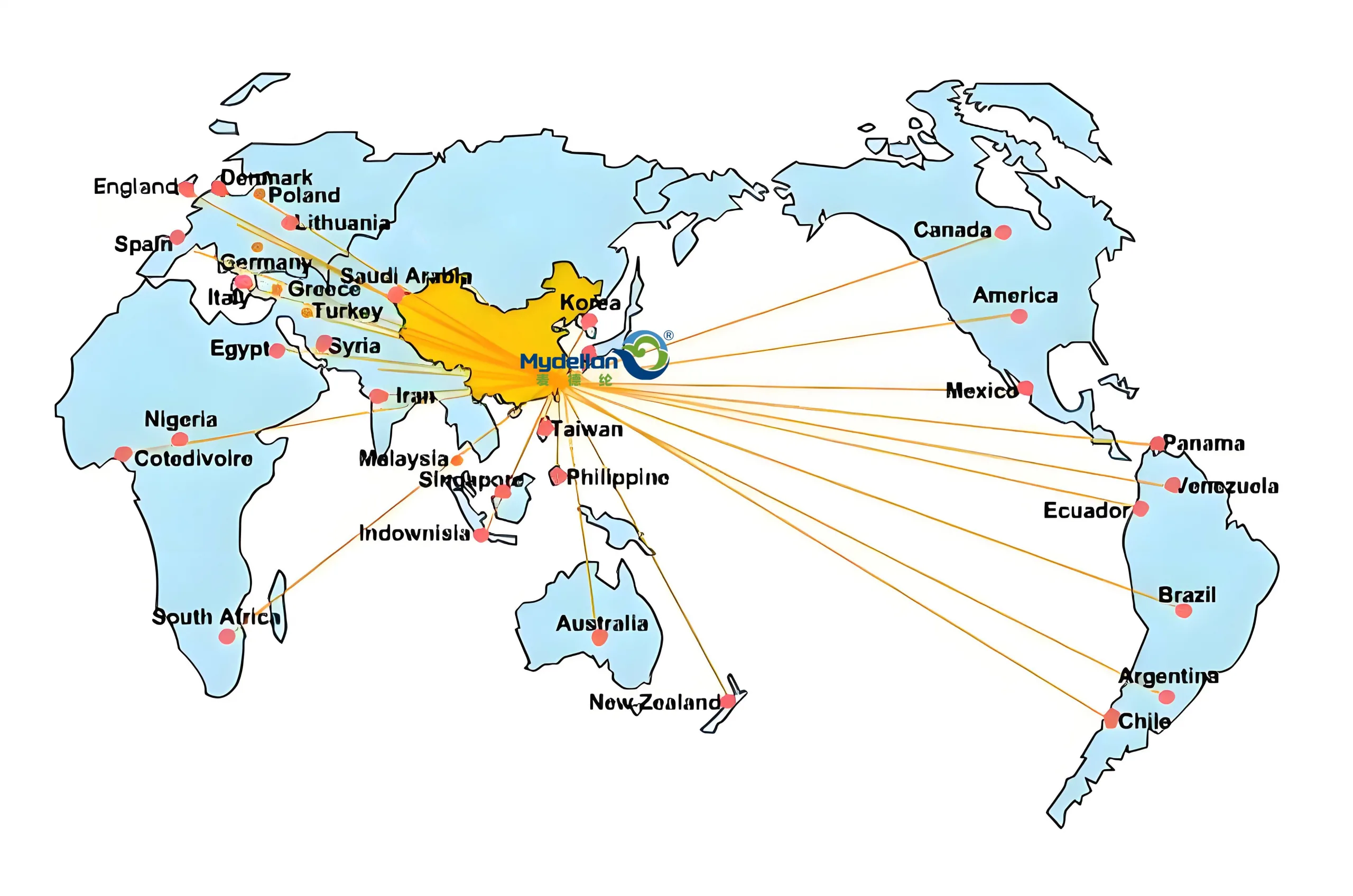

Mydellan Materials Company’s UHMWPE fibers range from 4D to 3600D, with the highest being 40,000D yarns. They are exported to many countries around the world, offering stable quality and earning the trust of customers. Welcome to inquire and place orders.

Contact us